“When the going gets tough.”

Blasogrind GTE 5

Gears and Grinding Specialist Tom Cappadona from Blaser Swisslube with Doug Kring, Applications Engineer at United Grinding Technologies

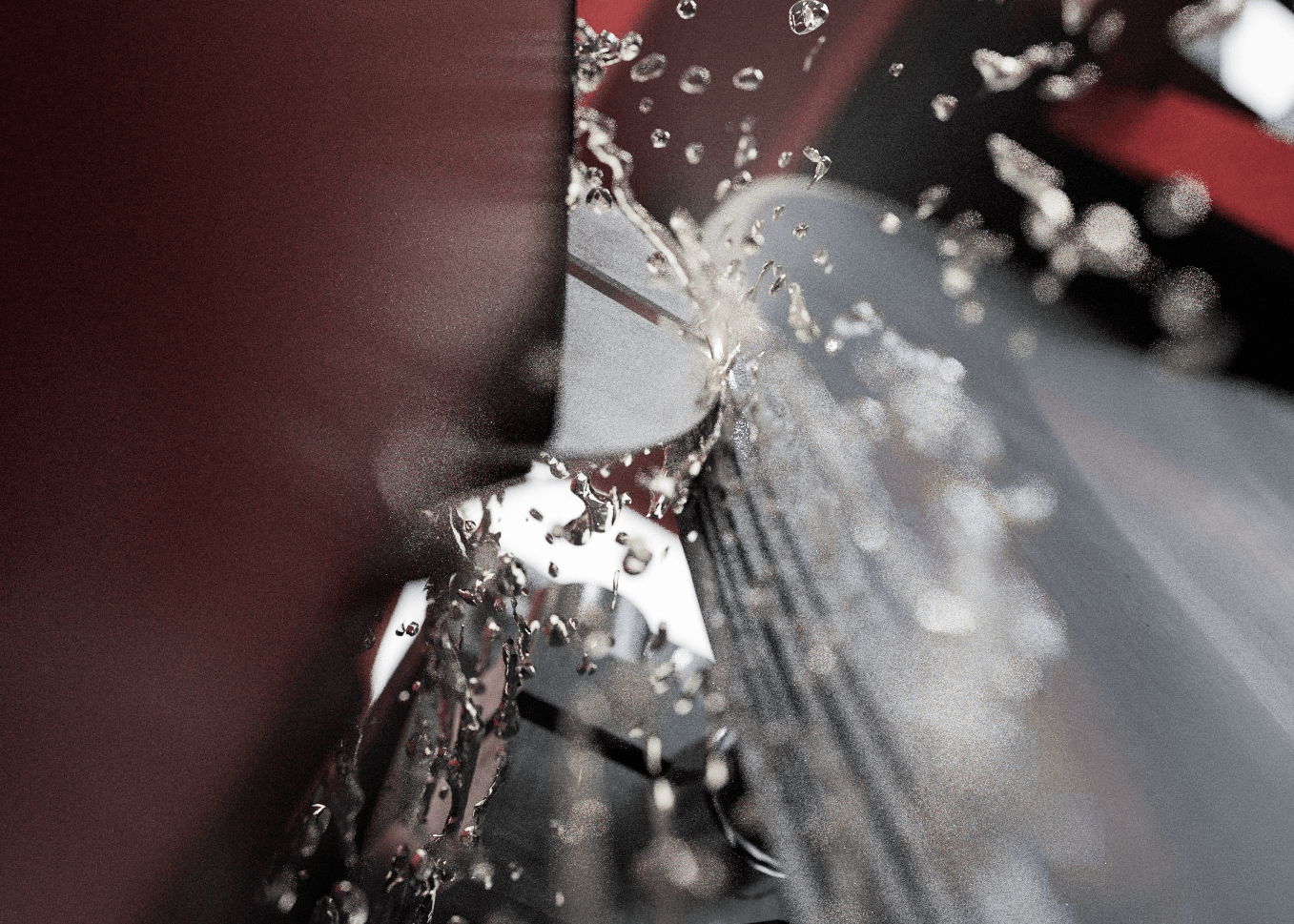

For combined EDM and grinding of hard and super hard materials

- High removal rate with hard and super hard materials such as PCD, CBN, ceramic cermet and tungsten carbide

- Excellent surface quality

- Prevents the release of cobalt when grinding tungsten carbide

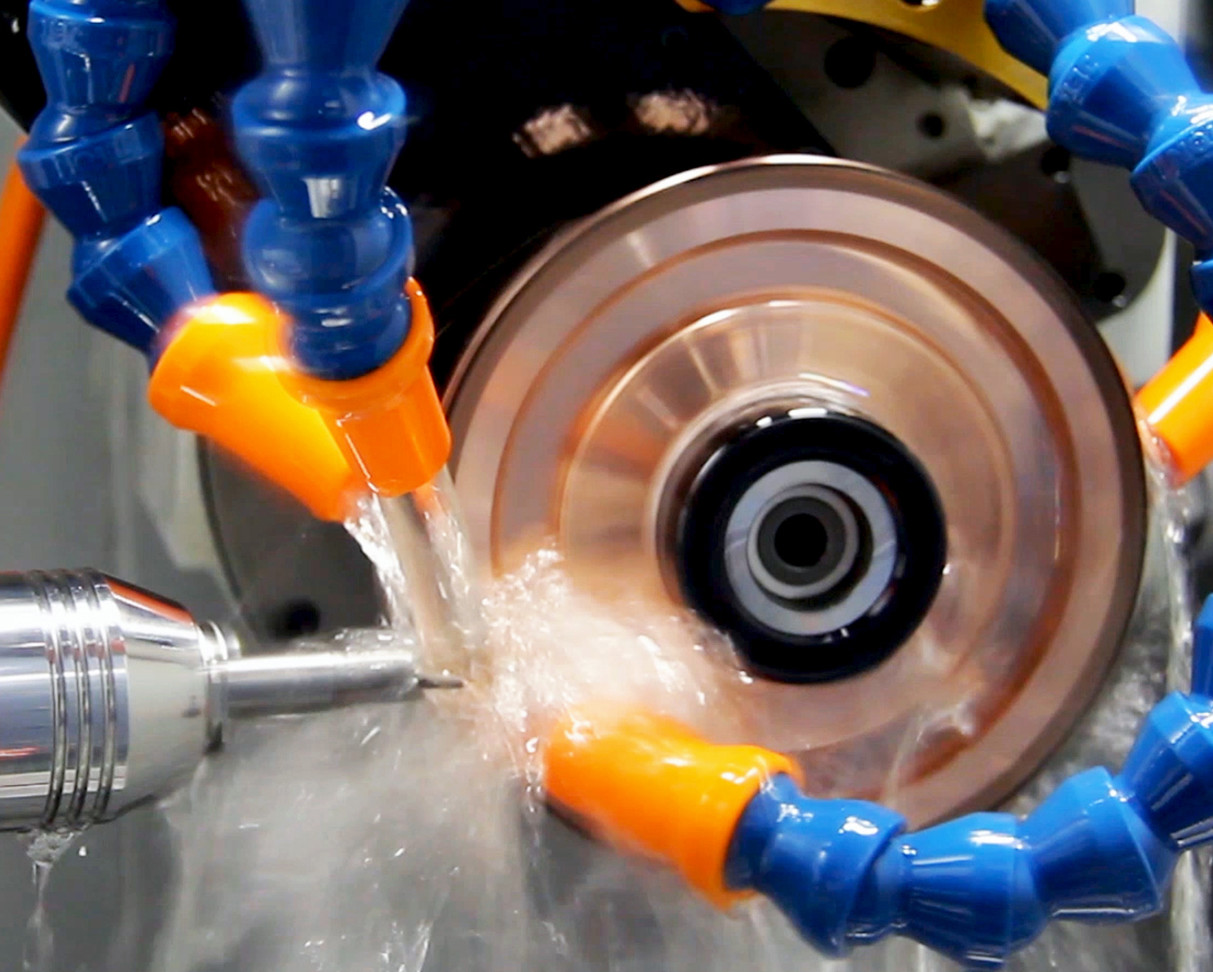

- Minimal mist and vapor formation for a pleasant work environment

- Colorless and transparent for a clear view of the spark condition

- GTL-based oil for long-term oxidation stability and good machine compatibility

For all major EDM grinding systems

- Low viscosity and high flashpoint ensure optimal spark gap, minimized electrode wear and high stock removal also with fine grid wheels

- Ultra-fast air release creates an optimal ionized channel and dielectric strength

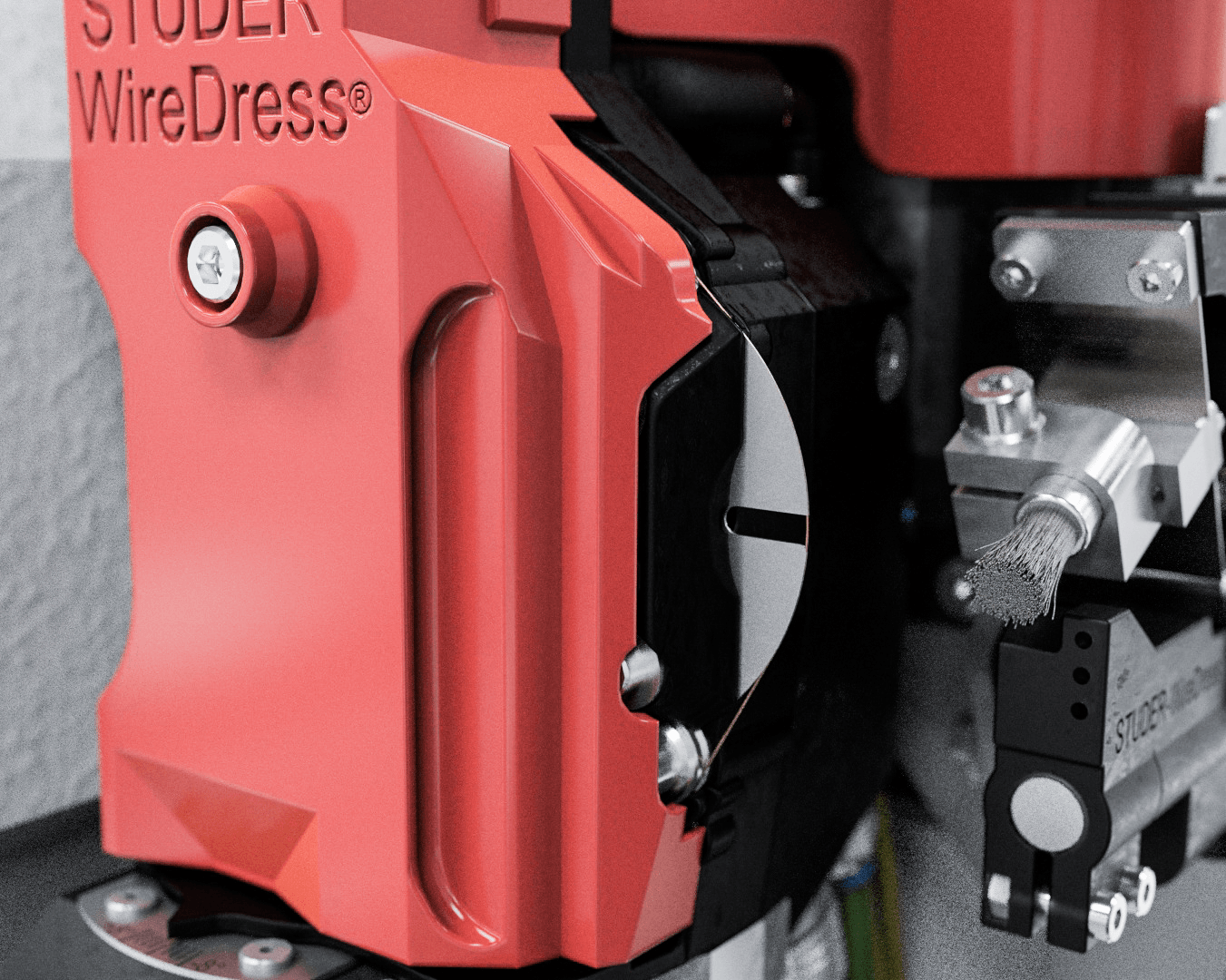

Grinding machines equipped with Studer WireDress

Anca EDG: PCD rotary eroding and carbide tool grinding in one

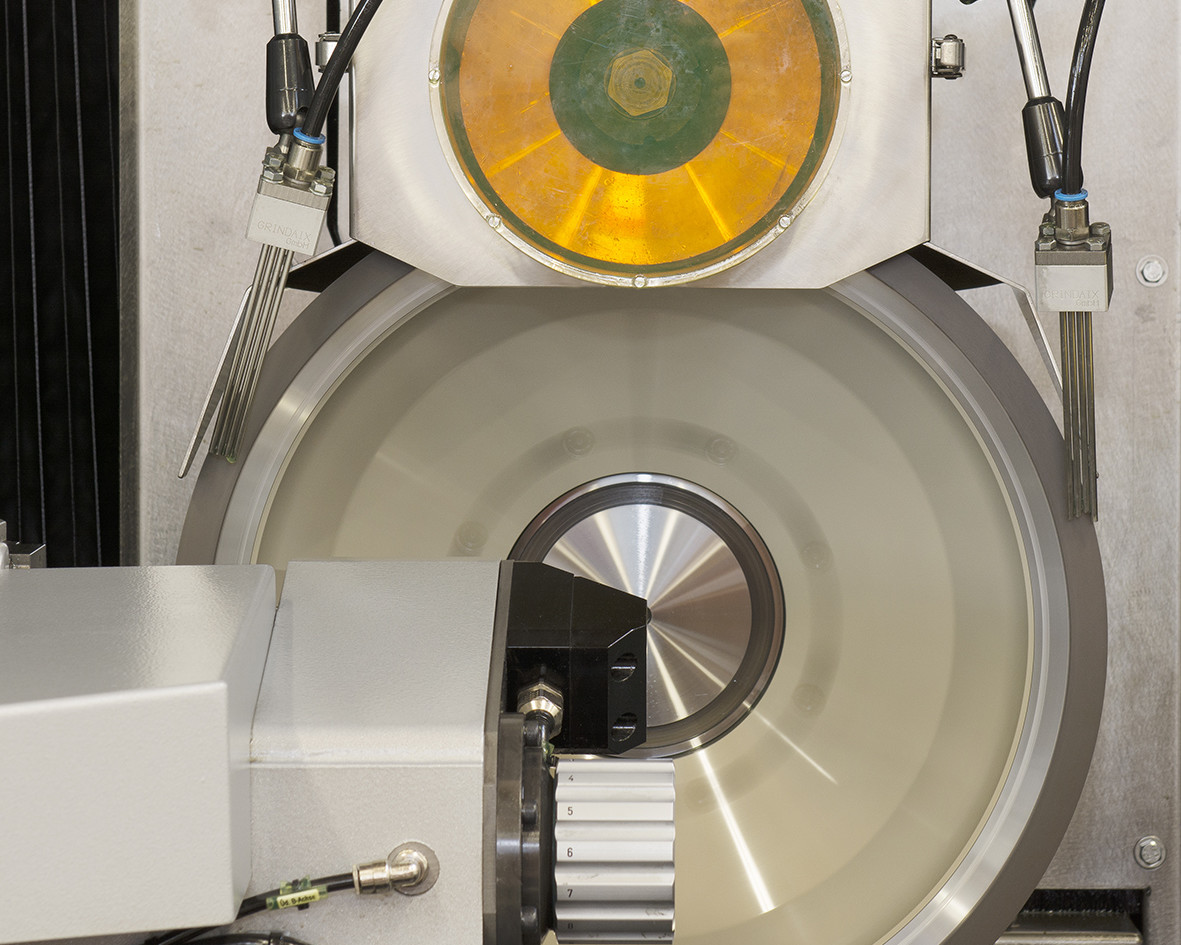

Agathon grinding machines equipped with PowerGrind technology

Request more info

I’d like to know more about Blasogrind GTE 5 and Blaser’s unique Liquid Tool.