System cleaner ensures good starting conditions

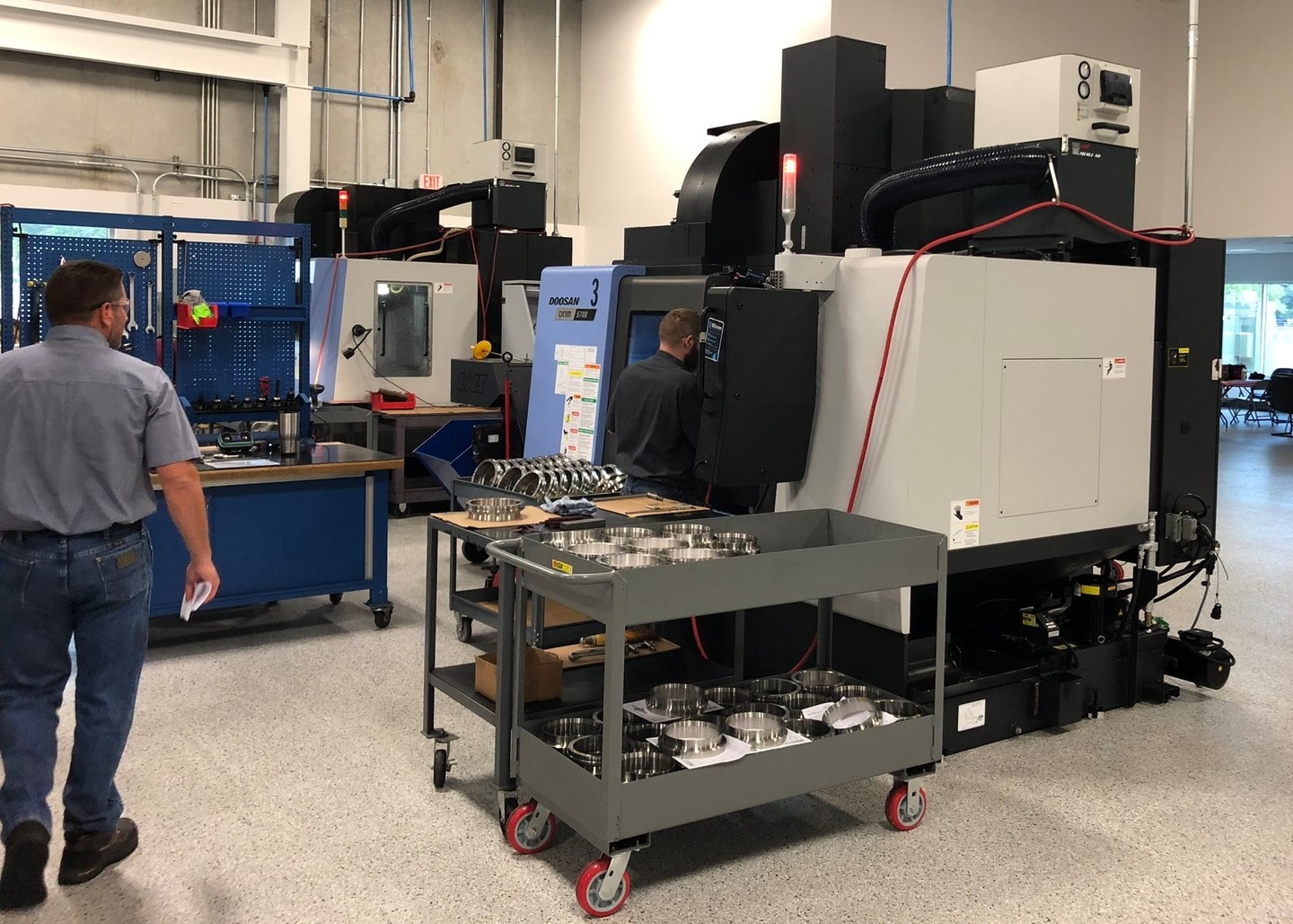

Thorough machine cleaning

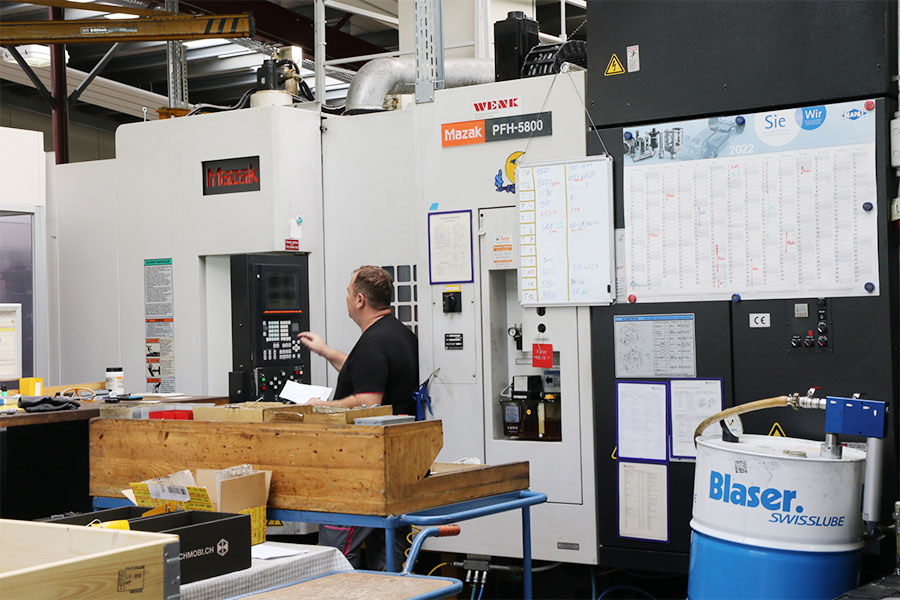

The fundament for an ideal maintenance of metalworking fluids is to ensure good starting conditions. That includes a thorough cleaning and rinsing of the machine or central system. A long sump life can only be achieved with professional cleaning before refilling a system.

While the emulsion tank, the chip conveyor, the filtration system, and the machine room can be cleaned with a high-pressure cleaner, the cleaning of the piping system with mechanical methods is only possible with great effort. System cleaners are therefore used to clean the non-accessible areas. They have special wetting agents that help wash off residues from areas that are hard to reach. When using such system cleaners, it is important to ensure a correct concentration and duration of use. The technical data sheets show the detailed procedure.

Other service products

In most applications, there is no need for additional service products, also called additives. In some cases, however, it may be economical to boost the pH value with an additive or eliminate stains on critical aluminum alloys. If foam control is a priority, calcium acetate can be used as an additive.