Microbial growth is not usually tolerated in traditional products because the ingredients suppress the growth of microorganisms in the ready-to-use product.

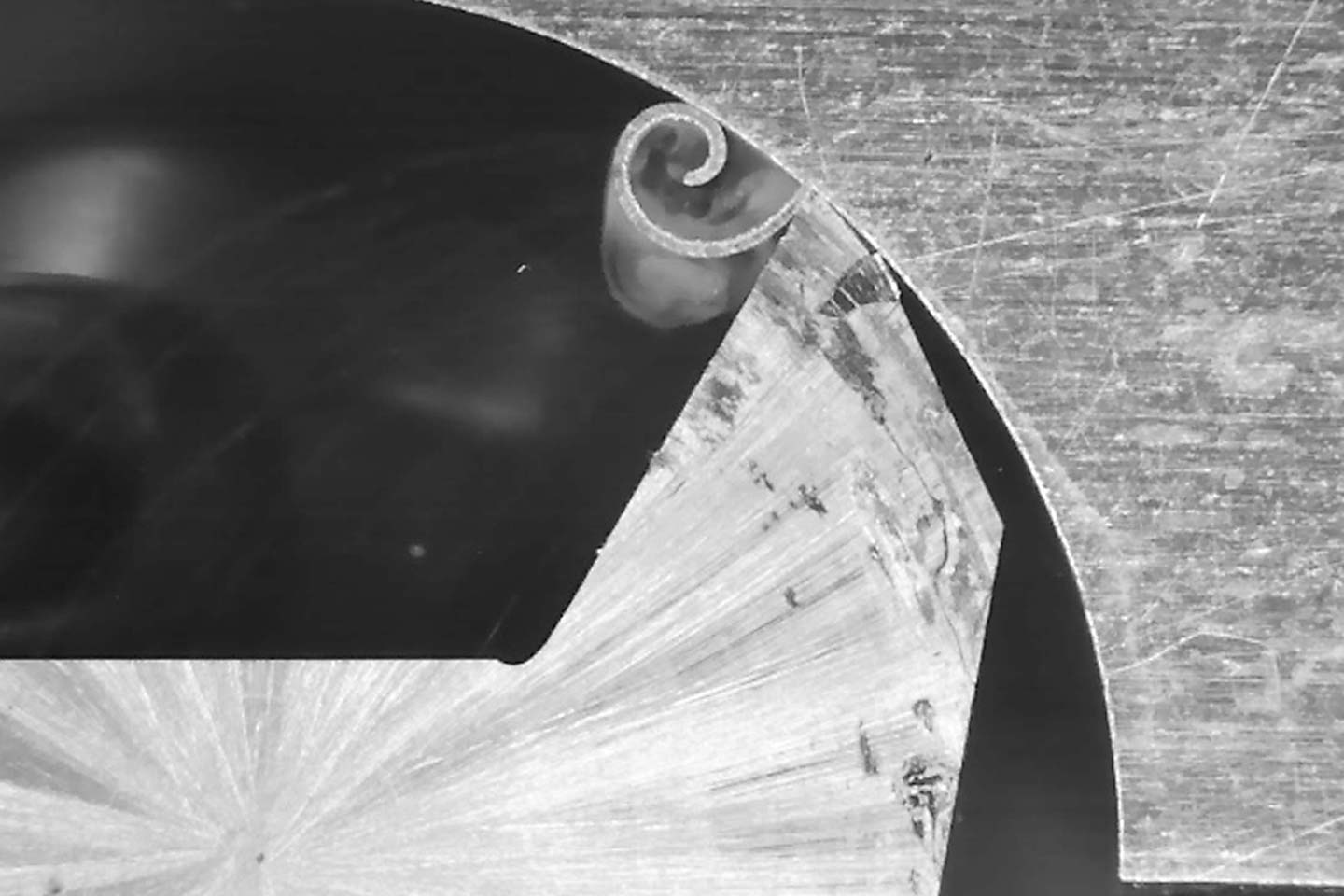

In order to check that everything is in order with the metalworking fluid, we use the so-called dip slide for analysis.

The dip slide is coated on both sides with a nutrient agar. If bacteria, yeast and/or mold are present, they will divide on the dip slide until they grow into a colony that is visible to the eye. This test tells us whether or not there is microbial growth and whether it involves bacteria or fungi

In the case of standard analysis, the evaluation of the samples takes around two to three working days. After we have completed our investigations, customers receive a report that contains all the parameters measured by the various laboratories and advice on whether control measures should be initiated.

Customer sample no. 1 from Germany features an empty dip slide. As no growth was detected on the dip slide, we can now be sure that the metalworking fluid used is stable.

In the case of customer sample no. 2 from Switzerland, a plater was set up and we can see that the organism identified as the primary bacterium is dominant. The characteristic colonies tell us that this bio-concept is also stable.

In my next blog post I will explain the specific analysis methods, such as PCR DNA analysis or the flow cytometry device, for which we have developed a special purification method designed for metalworking fluid samples in particular. These and other analysis methods are only used for certain customer samples and for research purposes and cannot be carried out by every metalworking fluid laboratory.