For you on site.

Also at GrindingHub 2024.

Hall 9, Booth C68

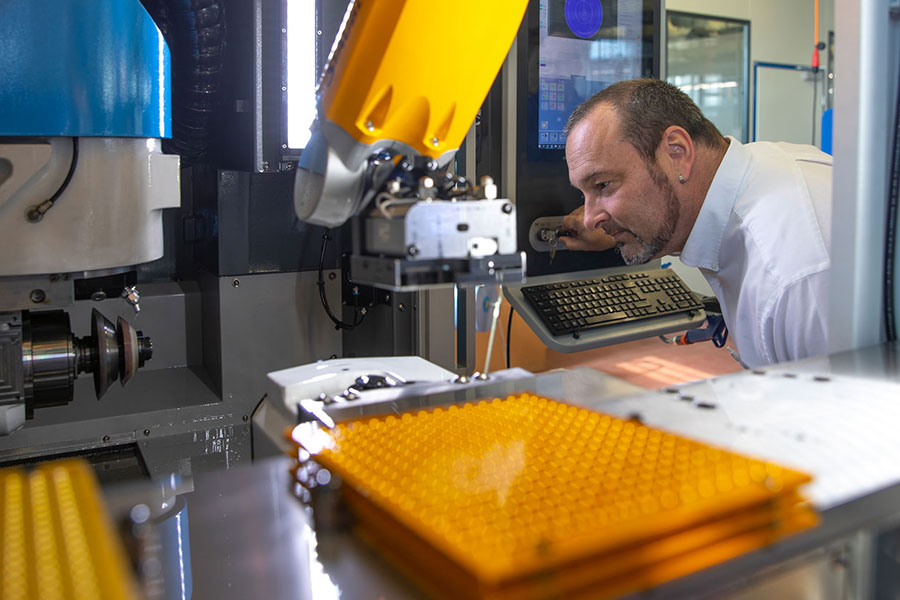

Our grinding experts Martin Reichhart and Simon Stalder know how to fight for every micron and every second.

Get the most out of your machines and tools

Our grinding experts analyze your entire production process, define the desired improvements together with you and prove in tests that these can be achieved.

- Stable processes and high machine availability

- Long tool and sump life

- Safe work environment and happy staff

- High workpiece quality and lower overall costs

When every micron counts

The new Blasogrind GTM 4 high-performance oil based on gas-to-liquid technology has been specially developed for precision grinding – regardless of industry, machine and material. It enables micron-precise machining of cutting and forming tools as well as medical implants, instruments and other precision parts made from materials such as carbide, HSS, stainless steel and ceramics.

Learn more about our Blasogrind GTM 4.

Benefit from our knowledge and experience

Decades of grinding experience have taught us there are complex correlations between chemistry and mechanics. We know that productivity, economic efficiency and machining quality are factors that critically depend on the choice and the quality of your metalworking fluid.

With our profound machining know-how and experience, customized services and excellent products, we help you fully capitalize on the potential of your machines and tools and turn your metalworking fluid into a key success factor – a Liquid ToolTM.

Visit us at GrindingHub 2024.

It’s worth it.

Would you like free admission? Register here with the ticket code F3D6HOV.