Monitoring the pH value and emulsion hardness

Besides the concentration, there are other parameters of water-miscible coolants that need to be monitored and measured: The pH value and the emulsion hardness are among the most important factors to check.

pH value

The pH value indicates the health of the coolant. A low pH value can cause corrosion or bad odors, a high pH value can cause stains on aluminum, excessive foaming, and skin irritations. The ideal pH value for most products is between 8.4 and 9.2.

The trend of the pH value over a certain period of time gives valuable information. A notable trend in one direction can be an early warning indicator. For example, a sharp drop of the pH value may be caused by a low emulsion concentration or high tramp oil leaking. A possible chemical contamination with an alkaline cleanser may have the opposite effect and result in a sharp increase of the pH value.

Monitoring the pH value is relatively easy: Using test strips, it should be checked and recorded at least once a week. The strips do not need to be calibrated, but it is important to be aware of their expiration date and to not use expired strips.

pH test strips

Consistent hardness, consistent emulsion quality

The determination of the emulsion hardness can also be helpful and provide insights: A consistent hardness ensures a consistent emulsion quality. Especially in applications with hard water and high water evaporation, a fast accumulation of hardness may occur. This can lead to an unstable emulsion or the formation of residue.

When reverse osmosis (RO) or deionized (DI) water is available, the hardness level can be managed by switching from hard water to RO or DI water based on the hardness level in the emulsion.

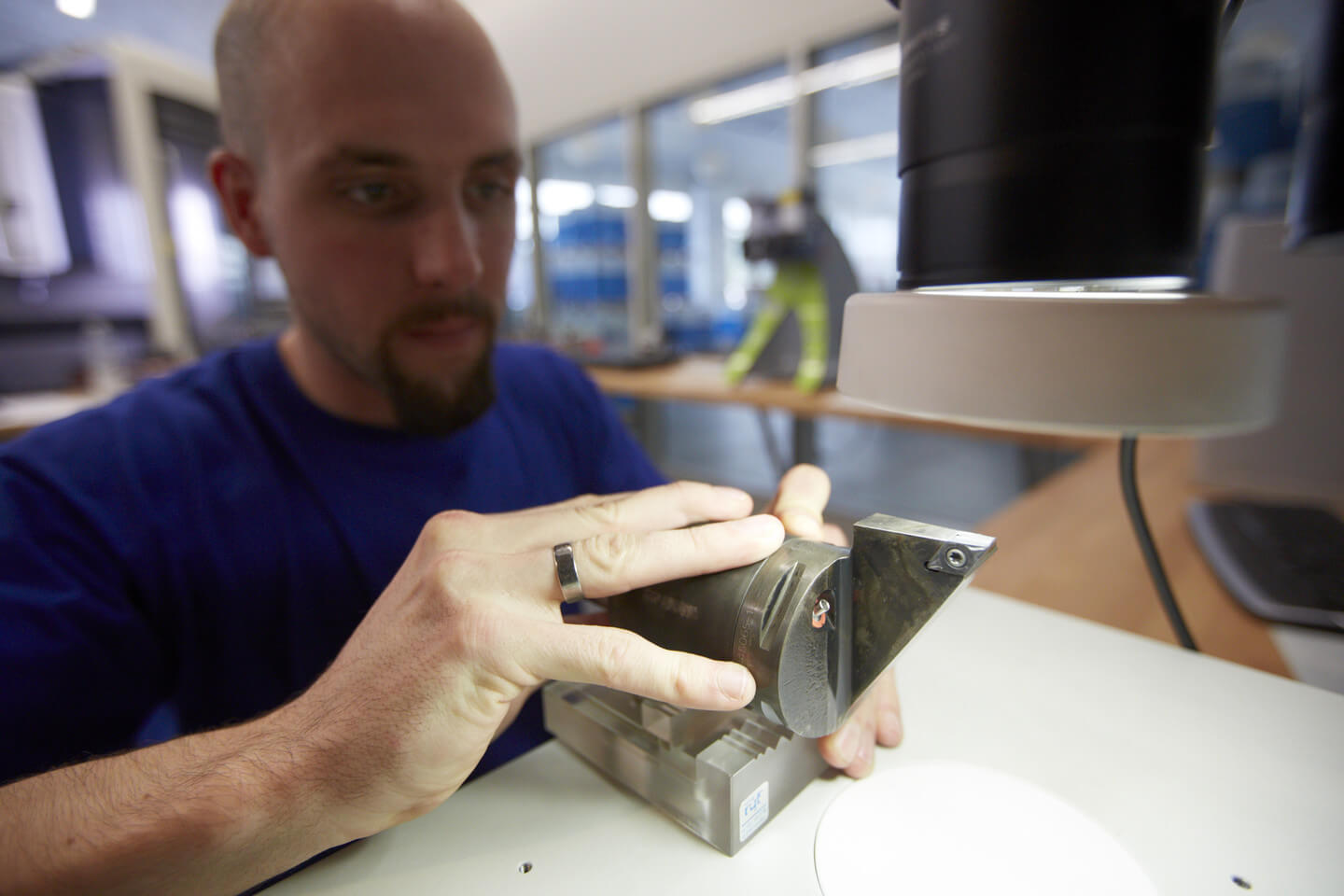

checking the hardness of the emulsion

Track the results

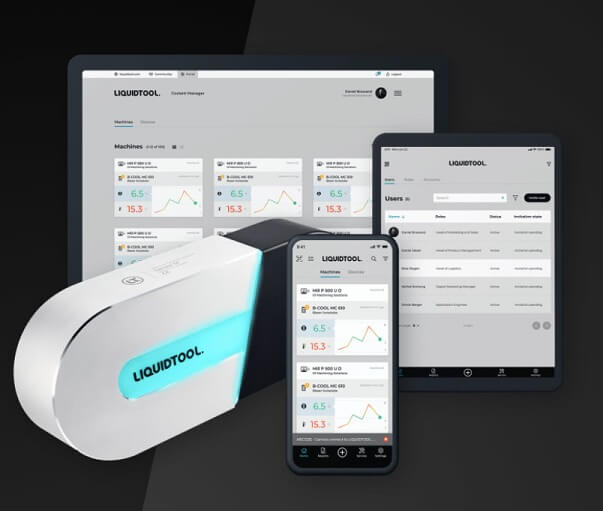

Alternatively, the coolant data can also be collected using an electronic device. Liquid Tool Systems AG offers a Coolant Manager.

Coolant Manager