Nitrite and microbial growth can affect the emulsion

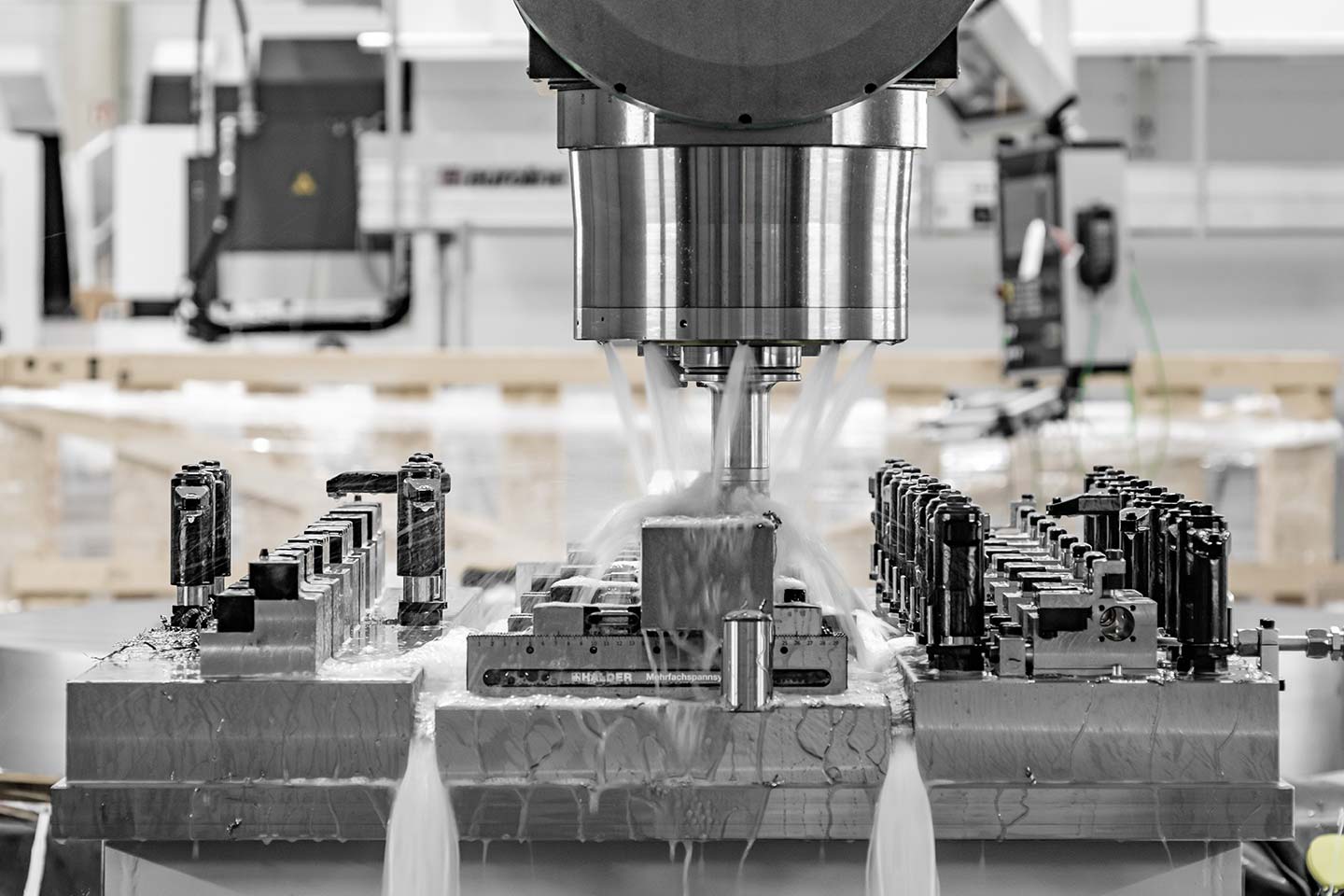

Besides daily visual checks, the measuring of the concentration and the monitoring of pH value and emulsion hardness, there are also other factors that need to be checked to ensure an ideal state of water-miscible coolants.

Regulations vary, but in Germany, the technical guideline TRGS 611 requests a weekly check of Nitrite in water-miscible metalworking fluids. With reason: If out of control, too high nitrite levels can bring the risk of Nitrosamine formation. The tests can be done with Nitrite test strips, the upper limit for Nitrite is 20 mg/l.

Nitrite test strips

Microbial growth – Dip slide test with growth of yeast, mold and bacteria

In the United Kingdom, the UKLA guideline requests a monitoring program for checking microbial growth in water-based metalworking fluids by means of a dip slide test. The main reason for this additional test is to ensure the safety of the fluid. However, microbiologists and safety officers question the value of this test. Only colony-forming microorganisms are detected and the treatment with biocide is not always the best corrective measure under the aspect of safety for operators. Good housekeeping in combination with monitoring and maintaining the concentration and pH value are considered to be efficient and effective to maintain the quality and safety of a water-based metalworking fluid.

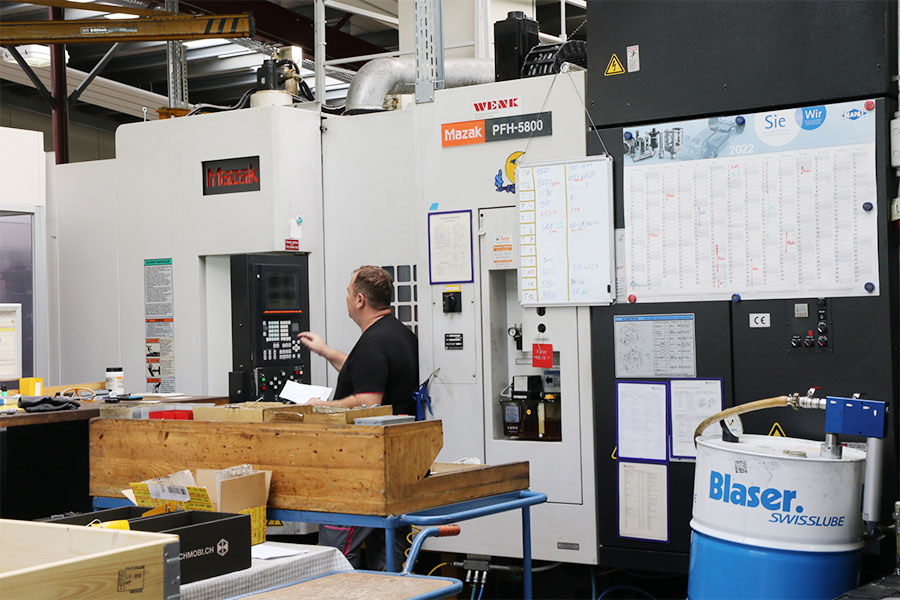

Blasocut – Bio-Concept

Blaser Swisslube offers water-miscible metalworking fluids called “Blasocut”, which do not contain any bactericides and foster the natural growth of benign bacteria. These bio-concept coolants are not only gentle to operators’ skin, but also do not need biocide treatment. Dip slide tests do not make sense, as bacterial growth is desired.