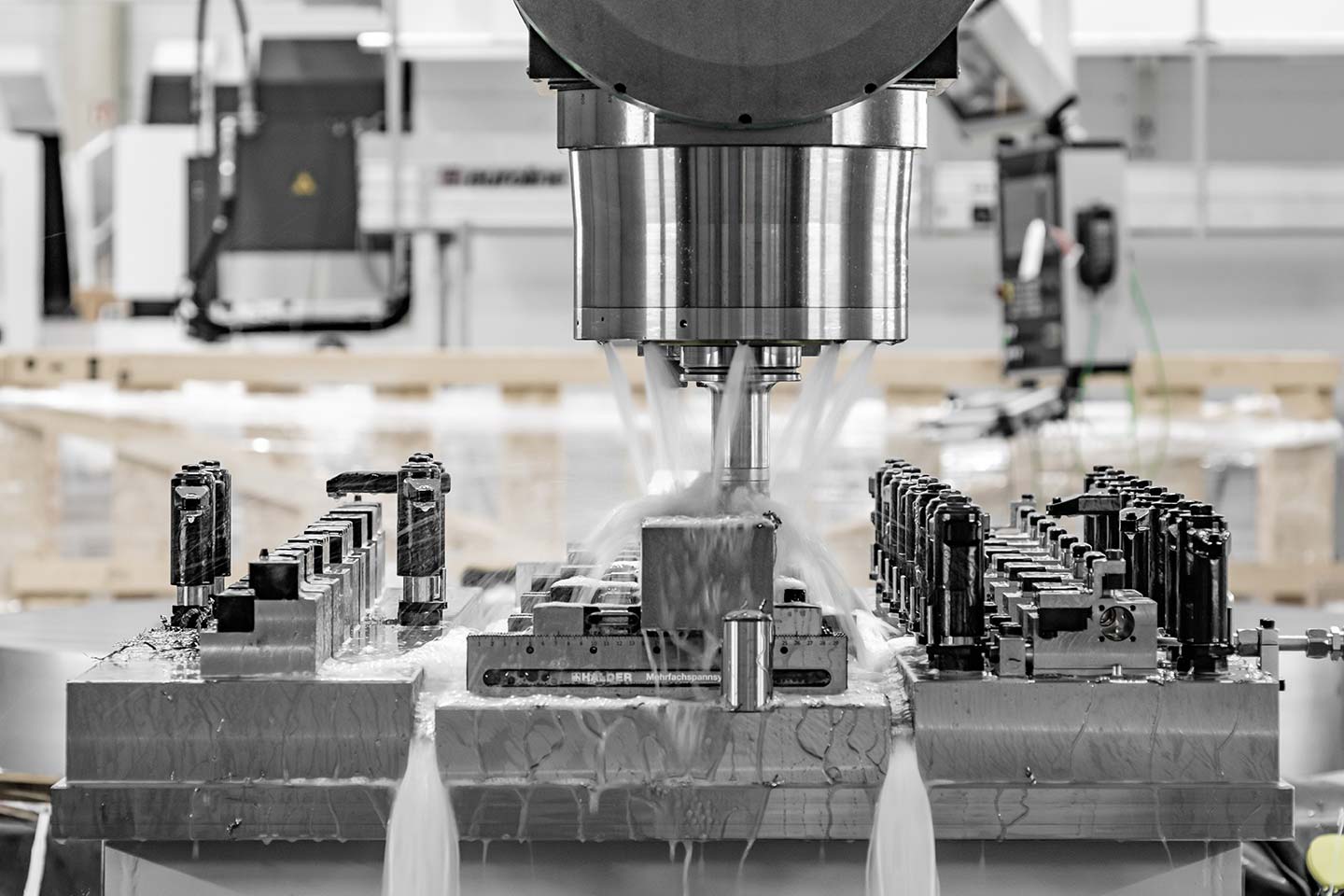

Mixing of metalworking fluids: water quality is a key factor

To optimize the overall process safety and quality, a metalworking fluid emulsion must be perfectly balanced and stable. To accomplish that, it is crucial to maintain an ideal water quality.

Unlike neat oils, which are used in metalworking operations in undiluted form, water-miscible fluids are normally diluted with water to form an emulsion. The concentrate consists of mineral oil or ester oil. Typically, the emulsion contains between 3 and 15% of concentrate.

The main component of metalworking fluid emulsions is water. The quality of the water, which can vary widely by source, region and country, has a significant impact on the emulsion quality and its sump life. Therefore, it is inevitable to evaluate key characteristics such as water hardness and chloride concentration.

Soft water increases foaming

The water hardness determines the foam behaviour of many metalworking fluid emulsions. If the water is soft (below 8° dH/140 ppm), increased foaming may occur. If the water is very hard (well above 20° dH/350 ppm), it may have negative effects such as formation of lime (calcium) soaps, weakened corrosion protection, reduced emulsion stability and shorter sump life.

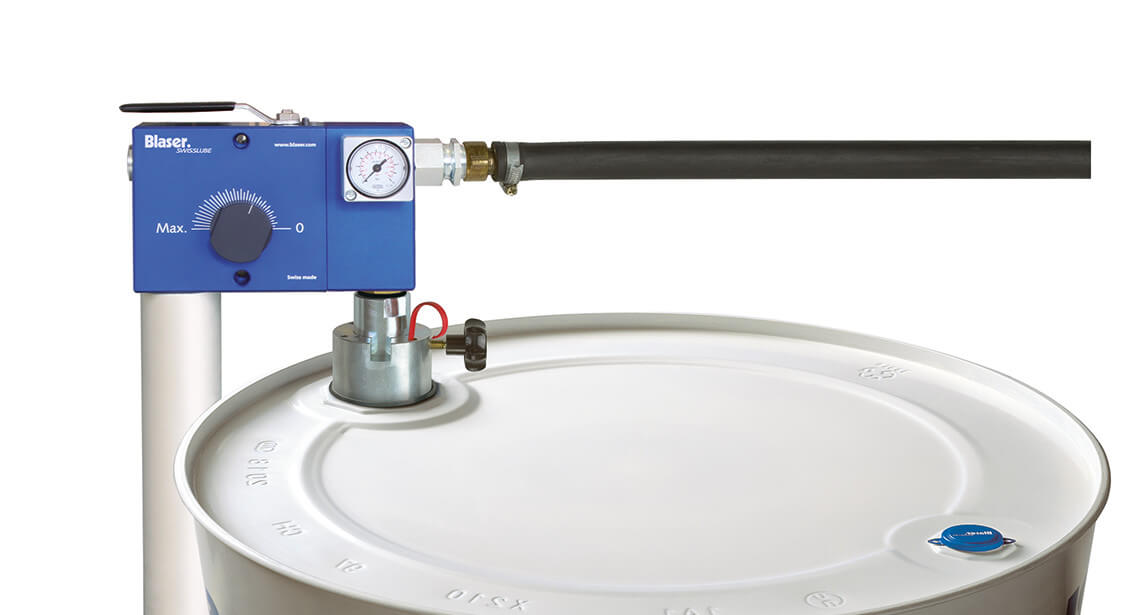

The Blaser experts treat the water in various ways to achieve the ideal water hardness level for each process: If the water is too soft, calcium acetate can be added to increase the hardness. If it is too hard, the water can be treated by ion exchange to make it softer. Other water treatment procedures like reversed osmosis (RO) or de-ionization (DI) remove all salts.

Water quality is key

High chloride leads to corrosion

Initial filling of machine

Another important quality parameter is the chloride concentration in the water. Chloride should not exceed 25 mg/l, as it accumulates in the coolant over time. High chloride concentration may lead to corrosion on machines and work pieces, negatively influencing the process safety and efficiency. If the chloride concentration is too high, the water can be treated with the RO/DI procedures to reduce or eliminate the chloride.

In most cases, normal tap water can be used for the initial filling of the machine, while treated water is recommended for the preparation of the top-up emulsion. However, some metalworking fluids need soft or even RO/DI water for a good long-term stability.

How to check the water quality

Both the water hardness and the chloride concentration can be checked directly on site with measuring strips. Additionally, many cities and regions provide information on the local water quality on the internet.

Once it is ensured that the water quality is ideal for the operation, the mixing process can start.

check water quality with measuring strips