Blasomill GT 22 – The cutting oil with a tangible added value

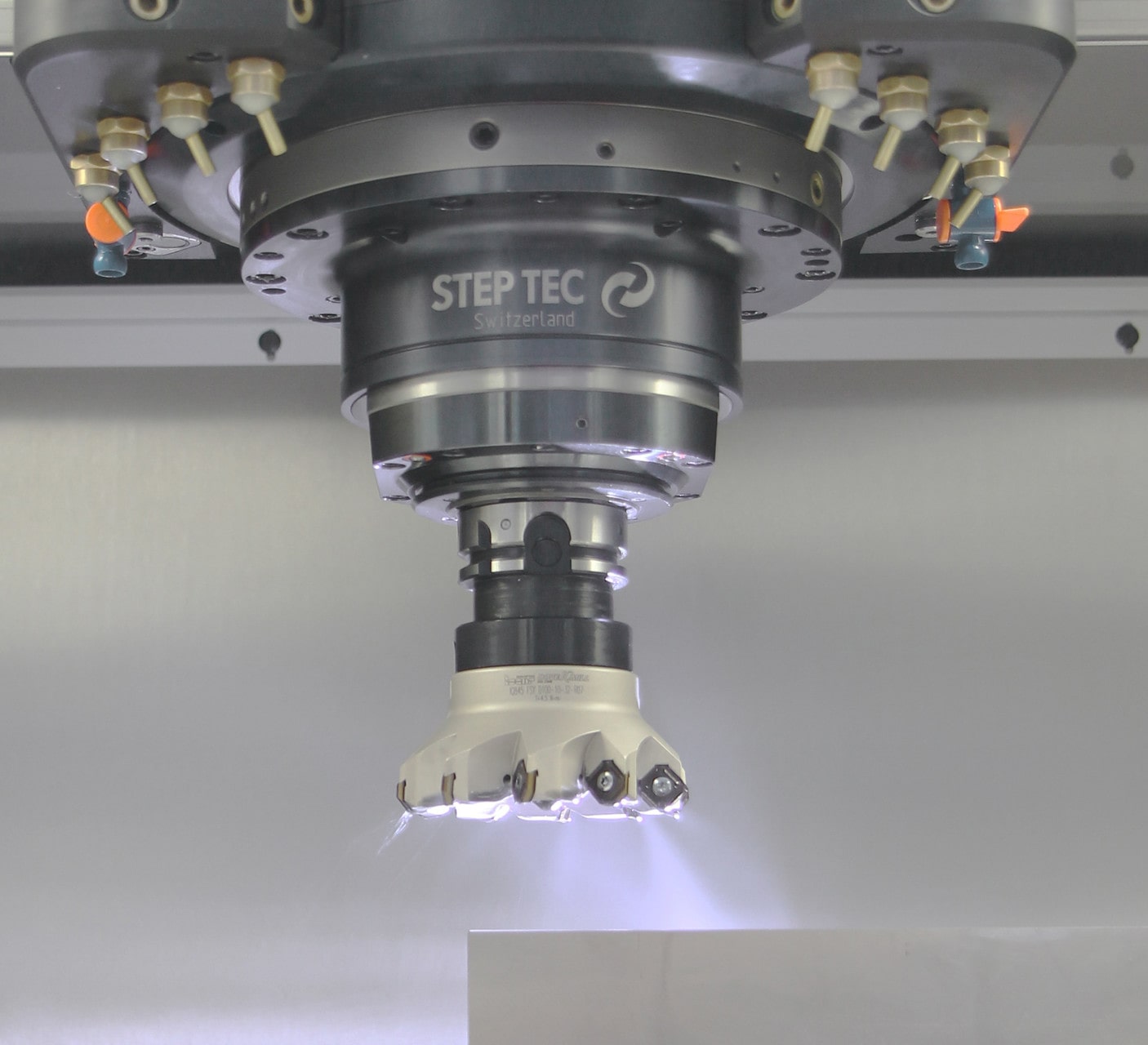

View of the production process

The world-renowned pepper mills by PSP Peugeot are sold in over 80 countries worldwide. The Liquid Tool by Blaser Swisslube helped PSP Peugeot improve their production process considerably by saving tool costs, omitting deburring and improving surface quality.

PSP Peugeot had heard of the Liquid Tool by Blaser Swisslube. The ability to achieve a measurable added value thanks to the optimum metalworking fluid evoked their interest. They wanted to improve the cycle and tool life in the demanding machining process of gear hobbing, in which the “poire” (pear), made of stainless steel S250, is ground.

Recording all parameters

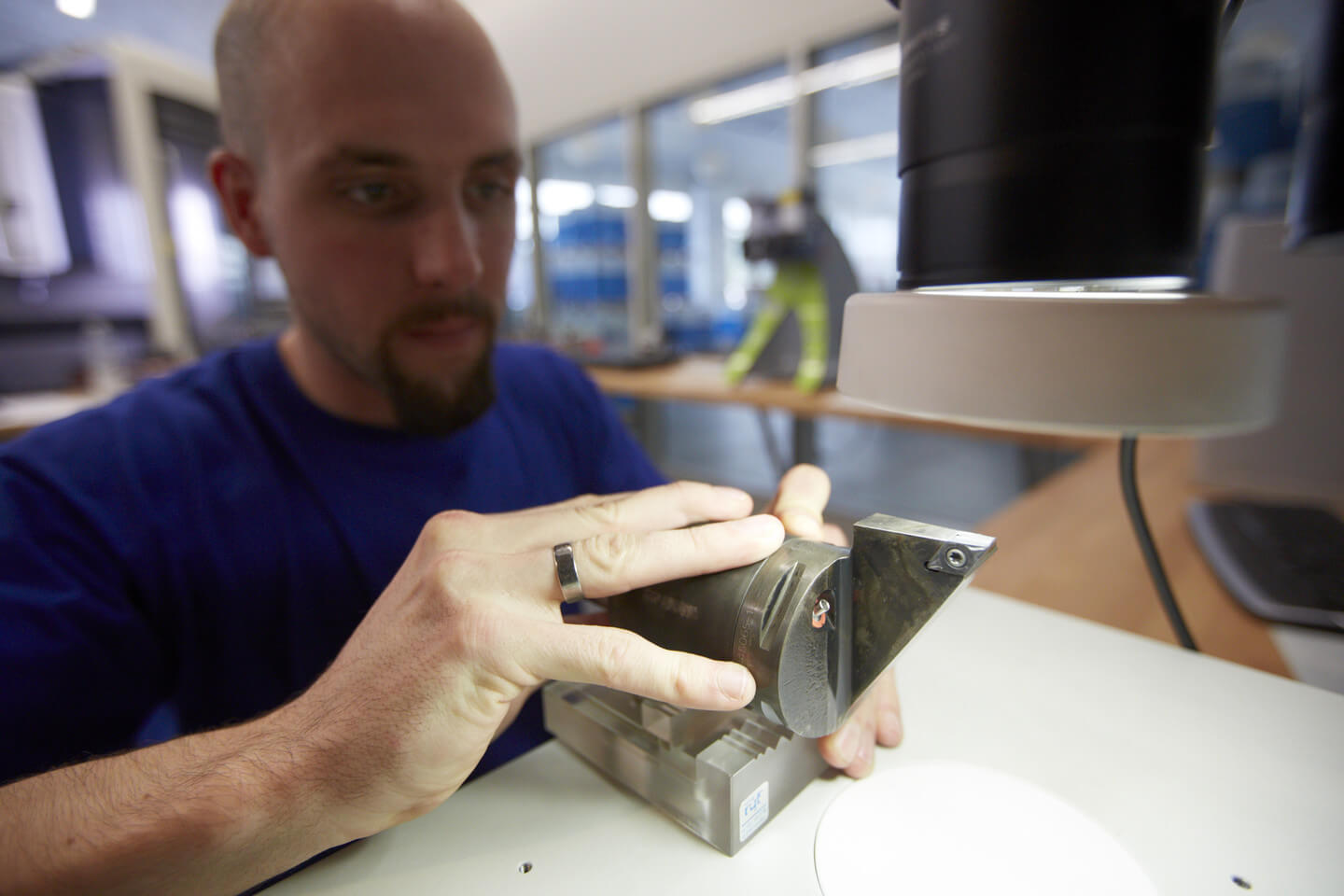

Ghislain Jouffroy, Methods Engineer at PSP Peugeot contacted Blaser Swisslube France. He was willing to perform machining tests with the recommended metalworking fluid Blasomill GT 22 on a TECH-TECH machine for three months. Blaser specialist Christophe Simon intensively oversaw this test phase, systematically recording all processing parameters.

The workpieces are aligned, guided, machined and then ejected by a spiral vibrator – everything is automated. “In addition to the metalworking fluid, we also switched the milling tool from HSS to carbide,” explains Christophe Simon. Per machine and year, 1.2 million “poires” are produced during shift operation, with a cycle time of 13 seconds per pear.

View of the production process

An impressive result

The improvements thoroughly impressed PSP Peugeot. Thanks to the Blaser metalworking fluid, 90,000 instead of the previous 30,000 workpieces could be produced – a plus of 200%, reducing the tool costs by a whole 21%. But that’s not all. Because the workpieces no longer heat up during the hobbing process, no more brows are formed, making the deburring process superfluous. “The Blasomill GT 22 releases the air very quickly, does not foam and is the perfect choice for this machining process at PSP Peugeot,” concludes Christophe Simon. The litre price of Blasomill GT 22 is higher than that of the previous oil, but the various savings result in net savings of EUR 25,173 per year. Ghislain Jouffroy is overjoyed: “Everything is running like clockwork and we are very satisfied.”

What the future will bring

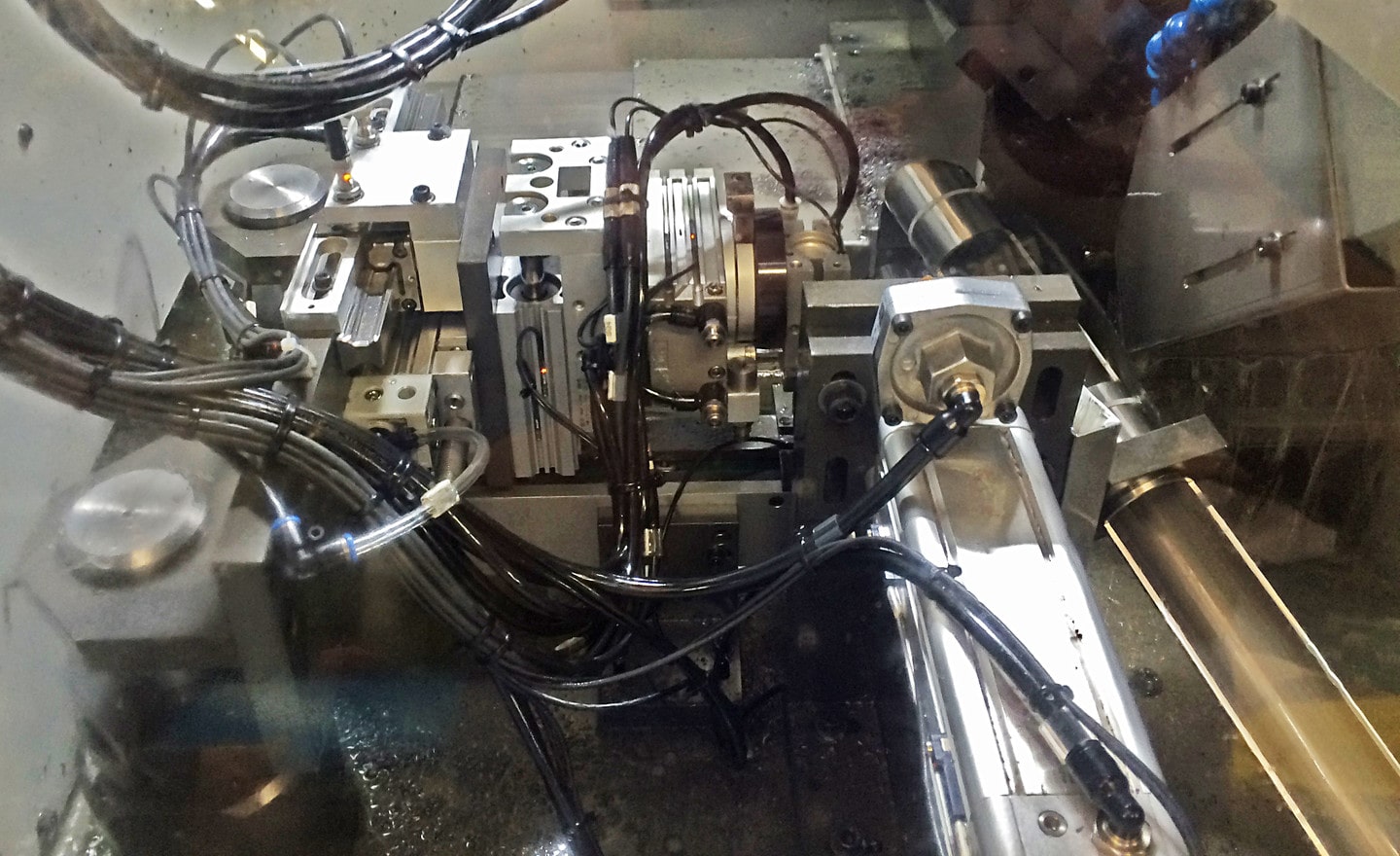

PSP Peugeot has found the right coolant partner in Blaser Swisslube. They do not want to rest on their laurels, but want to continuously optimize their processes together. Thus, for the next project, they want to jointly analyse and improve the operation of the turning lathes.

The Liquid Tool by Blaser Swisslube

Productivity, economic efficiency and machining quality are factors that critically depend on the choice and the quality of the metalworking fluid. “With our profound know-how and experience, customized services and excellent products, we help our customers to fully capitalize on the potential of machines and tools and to turn the metalworking fluid into a key success factor – a Liquid Tool,” says Marc Blaser, CEO of Blaser Swisslube.