by Bruno Christen | Oct 24, 2022 | Customer Cases

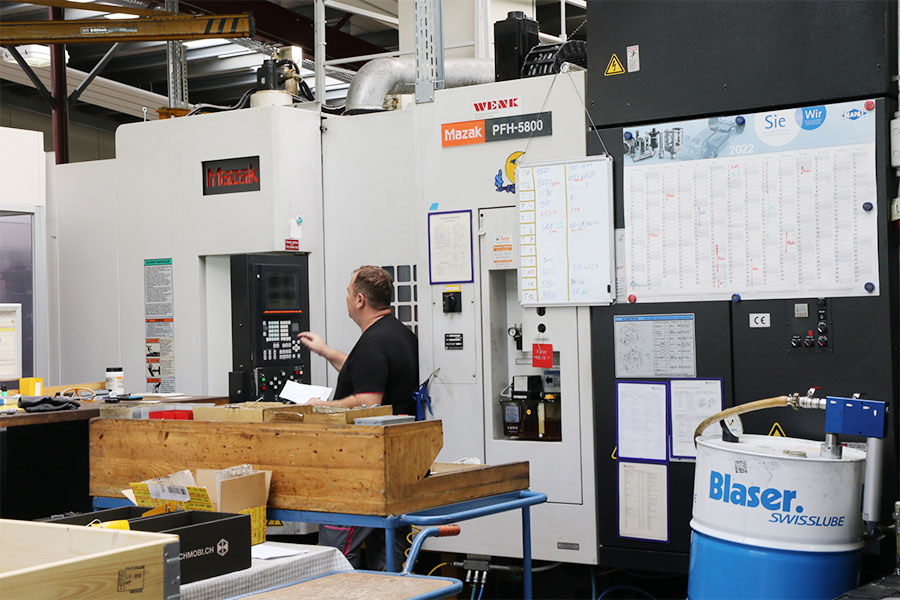

ChemValve-Schmid – Planning reliability and clean machines with B-Cool For three decades, leading PTFE industrial valve manufacturer ChemValve-Schmid AG has relied on metalworking fluids from Blaser Swisslube in its diverse machining processes. The demands on the metalworking fluid are changing continuously as new machines, materials and production sequences appear. Following detailed analysis, about four years ago the Blaser experts suggested switching to B-Cool 755, a water-miscible mineral oil-based metalworking fluid. The switch soon paid off: greater predictability, easier maintenance, reduced consumption, optimized skin compatibility and top efficiency are the outstanding results. ChemValve-Schmid AG, based in Welschenrohr in the Swiss canton of Solothurn, develops and produces high-quality industrial valves lined with PTFE for secure shut-off and regulation of gaseous, liquid or powdery media. ChemValve is a private and independent company that—with the finely crafted details of its sophisticated sealing systems, high manufacturing precision, a focus on innovation, and proprietary production machinery—has earned the status as one of the world’s leading PTFE valve manufacturers. An extensive network of distribution partners enables ChemValve to serve customers from various industry sectors in over 60 countries worldwide. Since its foundation in 1993, ChemValve has focused on maximum precision and quality in production. Blaser Swisslube has accompanied the company as a metalworking fluid partner ever since. Three decades in which production processes were constantly examined, analyzed and improved in close co-operation. “For 30 years, Blaser specialists have been working hand in hand with us, testing, checking and advising. The Blaser field service specialists all have one thing in mind: to get the best for the customer,” says Beat Allemann, Production Manager at ChemValve-Schmid AG. When ChemValve purchased new lathes in 2018, expanding its production, the company also revisited its metalworking fluid solution. “We were actually quite satisfied with the Blasocut metalworking fluid we had previously used. On Blaser’s initiative, however, we looked into switching over,” Allemann reports. Clean all-rounder Blaser application engineer Martin Haas recalls: “The production processes at ChemValve are complex. Up to 80 percent cast iron, but also titanium and other materials are milled and turned. We had the idea of trying B-Cool 755—a...

by Bruno Christen | May 16, 2022 | Customer Cases

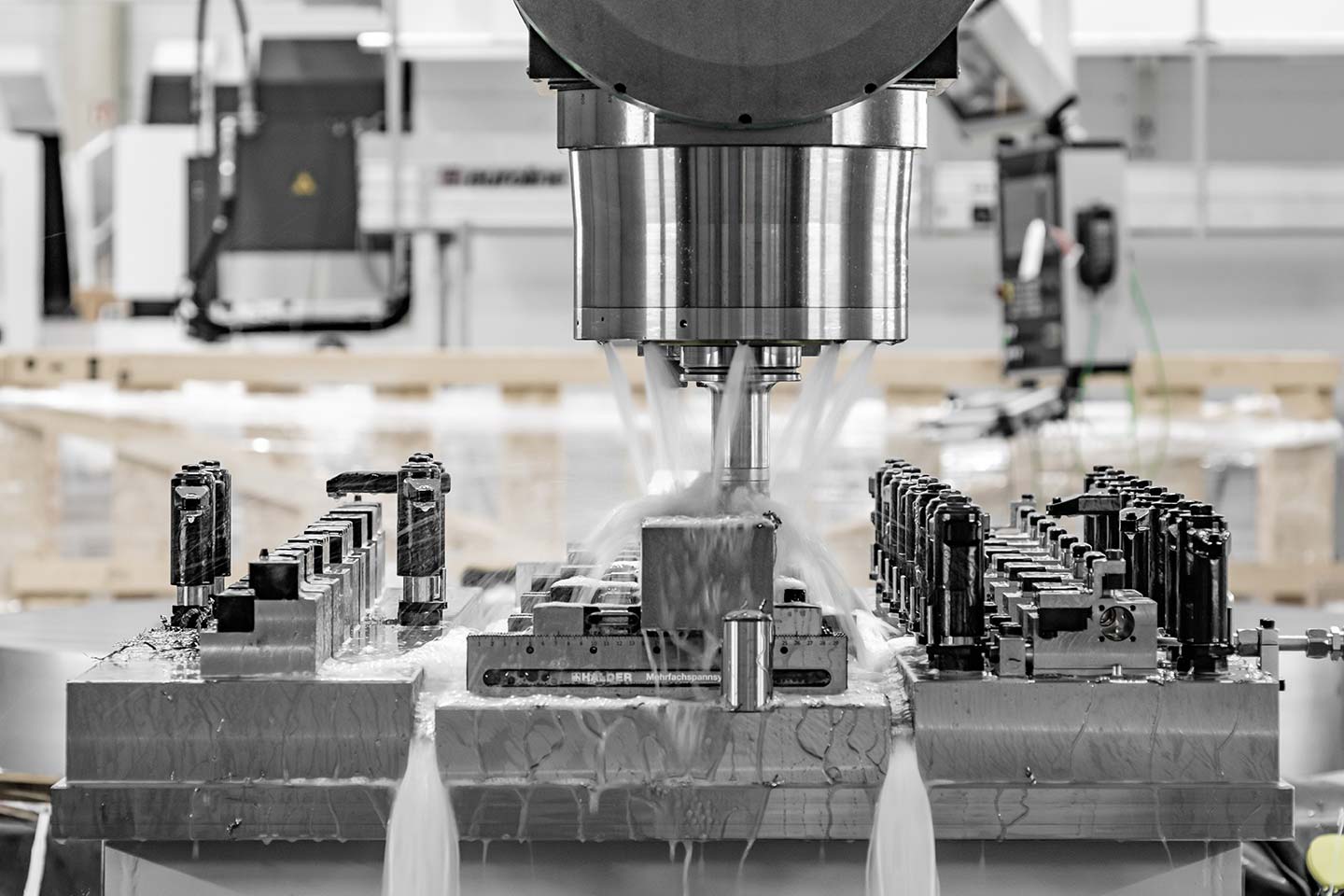

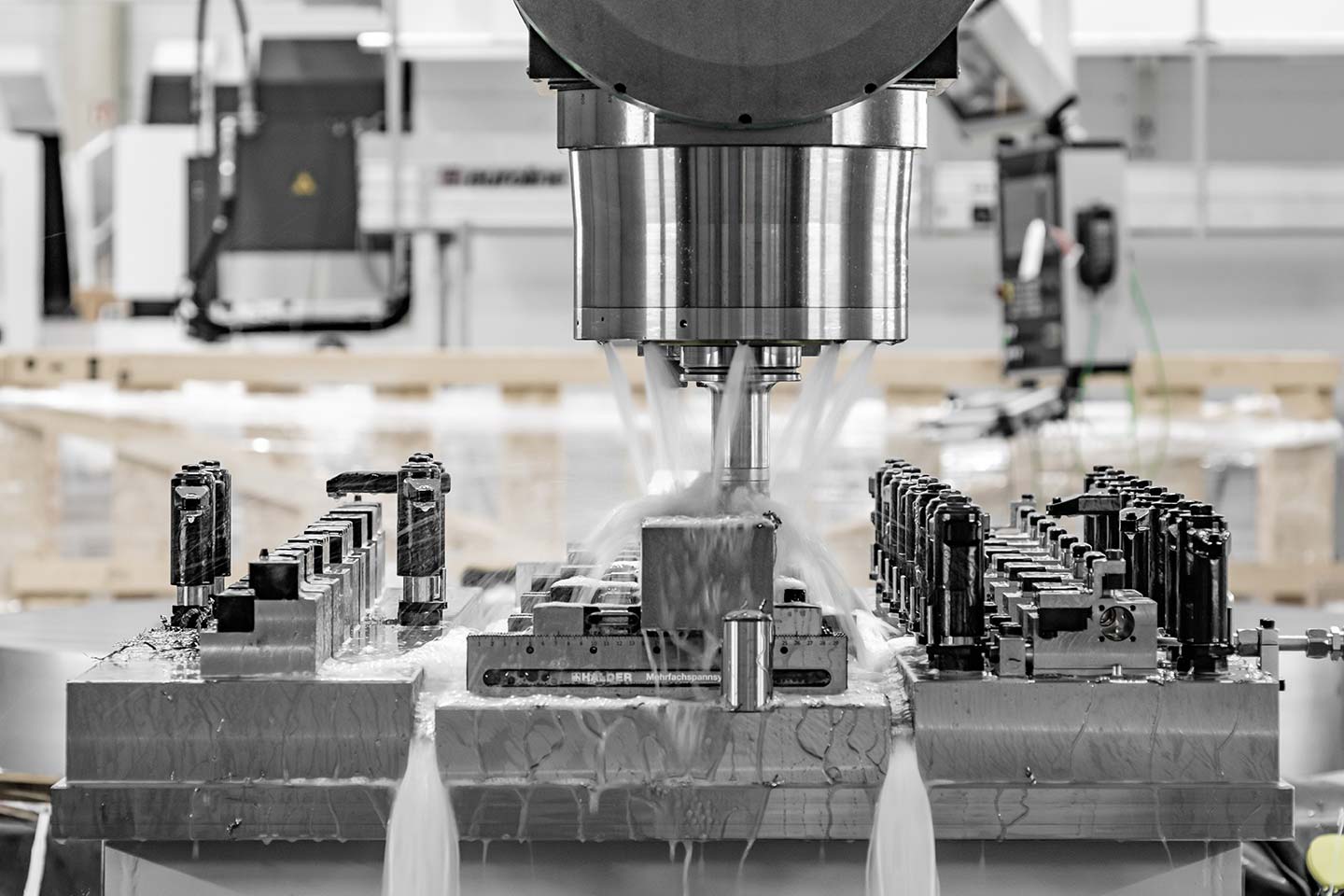

Combined expertise offers optimum process security A special kind of cooperation was witnessed in Baden-Württemberg in 2020-2021: Machine builders F. Zimmermann GmbH, tool experts from Mapal and metalworking fluid specialists from Blaser Swisslube, came together to work as an expert team to ensure the reliability and efficiency of a machine concept developed for machining titanium. The expertise of all those involved meant that it was possible to increase the service life of the tools used for titanium machining by a factor of seven, while at the same time guaranteeing process security. Neuhausen auf den Fildern is a small community about 4 kilometers east of Stuttgart Airport, where F. Zimmermann GmbH, founded in 1933, has its headquarters. Around 180 employees work at Zimmermann. The company produces milling machines and horizontal machining centers for the automotive and aerospace industries. The centerpieces of Zimmermann machines include, among other things, the patented milling heads that are produced in-house. The specialist offers a suitable milling solution for every system concept and every material, as well as requirements in terms of metal removing rates and surface quality. The combined expertise of the F. Zimmermann, Mapal and Blaser companies ensures optimal process reliability in titanium machining. “We recognize our particular strength in large, complex machines that can be individually adapted,” explains Steffen Nüssle, Export Sales Manager and Head of Application Technology at Zimmermann. “You’ll find Zimmermann machines wherever there is a need to process large-volume components.” Around 95 percent of the systems are “Made in Germany”, and most of the company’s suppliers are located within a radius of just 80 kilometers. Mapal has its headquarters within this 80-kilometer radius, a little further to the east of Baden-Württemberg, in Aalen. Looking back on a 70-year history packed with innovations, Mapal has long established itself as one of the world’s leading suppliers of precision metal cutting tools. Mapal is the global technology leader in the machining of cuboid components. The company’s key data make impressive reading: 5,000 employees, branches with production, sales and service in 25 countries, more than 450 technical consultants in the field, more than 300 trainees worldwide Individual production for titanium machining In 2020, experts from machine builder Zimmermann, tool manufacturer Mapal and Blaser Swisslube joined forces...

by Bruno Christen | May 11, 2022 | Customer Cases

Coolant service life of more than 15 years thanks to the Blaser bio-concept Swiss metalworking fluid specialist Blaser Swisslube is known for sustainable and effective coolant solutions. Pfiffner Messwandler AG has successfully used Blasocut BC 25 MD without interruption for over 15 years. Sustainability that pays off. The Blasocut product line with its unique bio concept has been part of Blaser Swisslube’s product portfolio for over 45 years. The Blasocut products contain no bactericides of any kind and are characterized by outstanding human compatibility and environmental friendliness. Thanks to their composition, they are designed for natural colonization by the water bacteria pseudomonas oleovorans (referred to as “primary bacteria”). This harmless waterborne bacterium is found across the globe in drinking water and acts as a natural stabilizer as it were. It leaves no space for the unwanted bacteria to grow and spread within the coolant. This results in a biological balance without any risk to health or destabilization of the coolant. Refractometer measurement by the customer. A sustainable coolant solution tailored to customer requirements “The central system at Pfiffner in Hirschthal was filled with Blasocut BC 25 MD by my predecessor in December 2005,” explains Marco Frey, the responsible application engineer. Pfiffner Messwandler AG is an industrial company that manufactures products for electricity suppliers and industrial companies. At the site in Hirschthal in the canton of Aargau, machining is carried out on materials ranging from aluminum to steel and copper. Blasocut BC 25 MD is optimally tailored to Pfiffner’s production conditions and customer requirements. Maintenance and monitoring for the emulsion A sample of the coolant is taken every three months to monitor the emulsion. This is then sent to the customer service laboratory of Blaser Swisslube in Hasle-Rüegsau. In the Blaser Lab, nitrite and sulfate levels, conductivity and other measurement values are determined. “In all these years of taking samples for Pfiffner, we have always obtained optimal values for these measurements,” explains Manuel Schläppi, Head of Customer Service at Blaser Swisslube. The concentration of coolant is checked on site by an employee every one to two weeks. “Care and maintenance are very important. In addition to this, the system is automatically simulated using a level sensor. Once a year, the machines and the chip conveyors are thoroughly cleaned,”...

by Avery1Media | Apr 26, 2022 | Customer Cases

Coolant optimizes complex ceramic grinding processes Producing high-quality ceramic parts places particularly high demands on the coolant used. In early 2021, Mannheim-based manufacturer, BCE Special Ceramics GmbH, thoroughly tested Swisslube’s high-performance coolant Synergy 915. With excellent results: the coolant service life was tripled, while the service life of the grinding wheels increased by 30 percent. Other benefits include better surface quality, lower abrasion, higher stability, higher machine availability and better human compatibility. The switch to Synergy 915 was a complete success. Founded in 1986, BCE Special Ceramics GmbH, manufactures customer-specific technical ceramic parts. The Mannheim-based company focuses on complex and new parts, prototypes, pilot series, individual parts and smaller batch sizes that are designed and machined. “We do not represent mass production, but rather quality, flexibility and consistent customer focus,” explains Dr. Ing. Torsten Weiß, Managing Director of BCE. For the highly specialized manufacturer, the right choice of material is an essential part of the process – starting with ceramic powder, which is adapted to customer requirements in collaboration with research institutes and suppliers. The production hall of BCE. Here, too, contamination from the previously used coolant is still visible. With 30 employees, BCE supplies customers in the medical, insulation, chemical and other industries. When Marcus Benz, a sales representaative from Blaser Swisslube, first met with BCE Project Engineer Christoph Greubel and Division Master, Kamil Irmak, in the winter of 2020, they discussed problems and possible improvements in production. “Of course, with such specialized manufacturing processes, the demands on the coolant are also very high. BCE’s main goals were to reliably achieve the customers’ desired level of accuracy, excellent surface quality, lower abrasion and better human compatibility,” recalls Marcus Benz. BCE Division Master, Kamil Irmak, reports: “The stability of the coolant previously used was insufficient, and there was also paint dissolution and deposits in the machine and tank.” A three-month test phase with the Blaser coolant Synergy 915 was started at the beginning of 2021. Synergy 915 is a fully synthetic high-performance coolant ideally suited for grinding processes. “This product delivers excellent surface quality, low consumption, high stability, excellent rinse behavior as well as...

by Avery1Media | Apr 26, 2022 | Customer Cases

Blasogrind GTC 7 reduces processing times by ten percent Founded in 1989 and headquartered in Nussloch, in Baden-Württemberg, Germany, Woitschach GmbH has developed over the decades into a high-tech company with a focus on the reconditioning of gear hobs, the manufacture of drilling, milling and reaming tools, as well as special tools. In the spring of 2020, those in charge explored the potential for efficiency increases together with the coolant experts from Blaser Swisslube. A test phase with the high-performance grinding oil Blasogrind GTC 7 yielded impressive results: an increase in efficiency of up to ten percent and better surface topography for the tools. The headquarters of Woitschach GmbH is located around ten kilometers south of Heidelberg, in the industrial area of Nussloch. The company was founded in 1989 by Andre Woitschach as a resharpening service. The first workshop operated out of a garage. 32 years later, Woitschach GmbH is a large, ISO-certified high-tech company in the tooling industry, with state-of-the-art machinery and enormous product diversification. Timo Woitschach, son of the founder and current head of the company: “We can proudly say that we are now not only a traditional resharpening company, but also a respected manufacturer of special tools, developing solutions in carbide and cermet. Our portfolio also includes the resharpening of gear cutting tools, the manufacture and reconditioning of solid carbide tools with brazed cutting edges, such as reamers.” Manufacturing takes place with 14 employees in two halls using 15 CNC machines and a production area over 1,000 square meters. The company is broadly positioned and produces for numerous industries ranging from mechanical engineering, dental technology, automotive suppliers, and die and mold making, right through to the tool industry. Satisfied look: Blaser application engineer Martin Reichhart and Woitschach company director Timo Woitschach. Exploring potential In April 2020, initial talks took place between the coolant specialists from Blaser Swisslube and the experts from Woitschach GmbH. The goal of these talks was to explore potential efficiency improvements in Woitschach’s production. Sales representative Marcus Benz and grinding expert Martin Reichhart from Blaser Swisslube shared experience from many decades in the tool grinding industry and gained insight into the specific requirements of Woitschach GmbH. “For us, it’s all about machining the gear hobs from carbide...

by Blaser Swisslube | May 27, 2021 | Customer Cases

26 percent longer tool life Company building in Fulenbach, Switzerland The specialists at Ramseier Werkzeugbau found themselves struggling with short tool life. This was because the coolant used was not able to efficiently dissipate the heat generated during turning processes. Series production was switched to B-Cool 9665 in cooperation with Blaser Swisslube. This not only extended tool life by 26 percent, but also reduced overall costs, increased productivity, optimized machine cleanliness and eliminated skin problems among employees. Based in Fulenbach in the canton of Solothurn, E. Ramseier AG, is active in the areas of tool manufacturing, mold design and plant engineering. It particularly specializes in the design and manufacture of perforating, pressing, bending, follow-up cutting tools and plastic injection molds. Ramseier Werkzeugbau has a versatile fleet of CNC turning and grinding machines, stamp grinding machines, surface grinding machines, wire erosion machines and many more. Thanks to its many years of experience in design and production, Ramseier Werkzeugbau enjoys the trust of well-known companies from all areas of the metalworking industry. Initial talks between Ramseier Werkzeugbau and Blaser Swisslube took place in 2017. The problem encountered by production managers at Ramseier was that extreme heat was generated during turning operations such as roughing or parting and grooving that could not be dissipated by the coolant used. As a result, neither the tool life nor the cutting values achieved were satisfactory. In addition to the main goal of increasing tool life, the aim was also to improve machine cleanliness and human compatibility because machine operators have experienced skin problems in the past. View of the shop floor Milan Golubovic, Head of Series Production at Ramseier Werkzeugbau, knew Blaser Swisslube application engineer Marco Frey from a previous collaboration with a metal cutting company. He was also familiar with the Blaser B-Cool 9665 coolant from his previous job and was always satisfied with the coolant’s performance. Together, Marco Frey and Milan Golubovic analyzed the situation at Production in Ramseier Werkzeugbau. The various processes were examined, tools, machines and materials were inspected. “We need to take a holistic view of all details to ensure we choose the best possible coolant. If the coolant is ideally matched and maintained for all processes, it becomes a liquid tool and increases efficiency and...

Recent Comments